REACTIVE DYES PRINTING SERIES

| Product Name | CI No | Shades |

|---|---|---|

| REACTIVE GOLDEN YELLOW P3R | YELLOW 12 | &nbps; |

| REACTIVE YELLOW HR | ORANGE 12 | &nbps; |

| REACTIVE YELLOW P6G | YELLOW 95 | &nbps; |

| REACTIVE YELLOW P4G | YELLOW 18 | &nbps; |

| REACTIVE ORANGE P2R | ORANGE 13 | &nbps; |

| REACTIVE ORANGE P4R | ORANGE 35 | &nbps; |

| REACTIVE RED P8B | RED 31 | &nbps; |

| REACTIVE RED P2B | RED 45 | &nbps; |

| REACTIVE RED P4B | RED 245 | &nbps; |

| REACTIVE RED PB | RED 24 | &nbps; |

| REACTIVE RED P4BN | RED 3:1 | &nbps; |

| REACTIVE RED P6B | RED 218 | &nbps; |

| REACTIVE RED P6BN | RED 76 | &nbps; |

| REACTIVE BLUE P3R | BLUE 49 | &nbps; |

| REACTIVE BLUE P3R | BLUE 49.1 | &nbps; |

| REACTIVE BLUE P5R | BLUE 13 | &nbps; |

| Product Name | CI No | Shades |

|---|---|---|

| REACTIVE TURQUOISE BLUE PGR | BLUE 72 | &nbps; |

| REACTIVE NAVY BLUE P2R | BLACK 39 | &nbps; |

| REACTIVE BLACK HN | BLACK 8 | &nbps; |

| REACTIVE BLACK PGR | NA | &nbps; |

| REACTIVE PURPLE P3R | VIOLET 1 | &nbps; |

| REACTIVE MAGENTA HB | VIOLET 12 | &nbps; |

| REACTIVE GREEN P4BD | GREEN 19 | &nbps; |

| REACTIVE BROWN P2R | BROWN 11 | &nbps; |

| REACTIVE BROWN P4R | BROWN 9 | &nbps; |

REACTIVE DYES VINYL SULFONE SERIES

| Product Name | CI No | Shades | |

|---|---|---|---|

| 0.5% | 2% | ||

| REACTIVE YELLOW FG | YELLOW 42 | &nbps; | &nbps; |

| REACTIVE GOLDEN YELLOW RNL | ORANGE 107 | &nbps; | &nbps; |

| REACTIVE ORANGE 3R | ORANGE 16 | &nbps; | &nbps; |

| REACTIVE YELLOW GL | YELLOW 37 | &nbps; | &nbps; |

| REACTIVE RED 5B | RED 35 | &nbps; | &nbps; |

| REACTIVE RED BS | RED 111 | &nbps; | &nbps; |

| REACTIVE RED BB | RED 21 | &nbps; | &nbps; |

| REACTIVE VIOLET 5R | VIOLET 5 | &nbps; | &nbps; |

| REACTIVE TURQ BLUE HC-G | BLUE 21 | &nbps; | &nbps; |

| REACTIVE BLUE R | BLUE 19 | &nbps; | &nbps; |

| REACTIVE BRILL GREEN 6B | BLUE 38 | &nbps; | &nbps; |

| REACTIVE NAVY BLUE RGB | BLUE 250 | &nbps; | &nbps; |

| REACTIVE NAVY-BLUE GG | BLUE 203 | &nbps; | &nbps; |

| REACTIVE BLACK RL | BLACK 31 | &nbps; | &nbps; |

| REACTIVE BLACK B | BLACK 5 | &nbps; | &nbps; |

| REACTIVE BROWN GR | BROWN 18 | &nbps; | &nbps; |

REACTIVE DYES BI FUNCTIONAL MILD EXHAUST SERIES

| Product Name | CI No | Shades | |

|---|---|---|---|

| 0.5% | 2% | ||

| REACTIVE YELLOW ME4GL | YELLOW 160 | &nbps; | &nbps; |

| REACTIVE GOLDEN YELLOW MERL | YELLOW 145 | &nbps; | &nbps; |

| REACTIVE GOLDEN YELLOW 3RS | YELLOW 176 | &nbps; | &nbps; |

| REACTIVE ORANGE ME2RL | ORANGE 122 | &nbps; | &nbps; |

| REACTIVE RED ME4BL | RED 195 | &nbps; | &nbps; |

| REACTIVE RED ME6BL | RED 250/RED 196 | &nbps; | &nbps; |

| REACTIVE RED RB | RED 198 | &nbps; | &nbps; |

| REACTIVE RED ME3BL | RED 194 | &nbps; | &nbps; |

| REACTIVE RED MEBF | RED 222 | &nbps; | &nbps; |

| REACTIVE BLUE ME2RL | BLUE 248 | &nbps; | &nbps; |

| REACTIVE BLUE BB | BLUE 220 | &nbps; | &nbps; |

| REACTIVE BLUE RNG | BLUE 187 | &nbps; | &nbps; |

| REACTIVE BLUE BRF | BLUE 221 | &nbps; | &nbps; |

| REACTIVE BLUE BF | BLUE 222 | &nbps; | &nbps; |

| REACTIVE NAVY BLUE ME2GL | BLUE 194 | &nbps; | &nbps; |

REACTIVE DYES HIGH EXHAUST SERIE

| Product Name | CI No | Shades | |

|---|---|---|---|

| 0.5% | 2% | ||

| REACTIVE YELLOW HE4G | YELLOW 81 | &nbps; | &nbps; |

| REACTIVE YELLOW HE6G | YELLOW 135 | &nbps; | &nbps; |

| REACTIVE GOLDEN YELLOW HE4R | YELLOW 84 | &nbps; | &nbps; |

| REACTIVE YELLOW HER | YELLOW 84 A | &nbps; | &nbps; |

| REACTIVE YELLOW HE7GL | YELLOW 186 | &nbps; | &nbps; |

| REACTIVE ORANGE HER | ORANGE 84 | &nbps; | &nbps; |

| REACTIVE ORANGE HE2R | ORANGE 94 | &nbps; | &nbps; |

| REACTIVE RED HE3B | RED 120 | &nbps; | &nbps; |

| REACTIVE RED HE7B | RED 141 | &nbps; | &nbps; |

| REACTIVE RED HE8B | RED 152 | &nbps; | &nbps; |

| REACTIVE BLUE HEGN | BLUE 198 | &nbps; | &nbps; |

| REACTIVE NAVY-BLUE RX | BLUE 59 | &nbps; | &nbps; |

| REACTIVE NAVY-BLUE HER | BLUE 171 | &nbps; | &nbps; |

| REACTIVE BLUE HE2R | BLUE 172 | &nbps; | &nbps; |

| REACTIVE BLUE HERD | BLUE 160 | &nbps; | &nbps; |

| REACTIVE BLACK HEBL | BLACK 160 | &nbps; | &nbps; |

REACTIVE DYES BLACK SERIES

| Product Name | CI No | Shades | |

|---|---|---|---|

| 0.5% | 2% | ||

| REACTIVE BLACK WNN | MIX | &nbps; | &nbps; |

| REACTIVE BLACK GDNN | MIX | &nbps; | &nbps; |

| REACTIVE SUPER BLACK R | MIX | &nbps; | &nbps; |

| REACTIVE SUPER BLACK G | MIX | &nbps; | &nbps; |

| REACTIVE BLACK VSR | MIX | &nbps; | &nbps; |

| REACTIVE BLACK DNN | MIX | &nbps; | &nbps; |

REACTVE DYES COLD SERIES

| Product Name | CI No | Shades | |

|---|---|---|---|

| 0.5% | 2% | ||

| REACTIVE RED M5B | RED 2 | &nbps; | &nbps; |

| REACTIVE RED M8B | RED 11 | &nbps; | &nbps; |

| REACTIVE MAGENTA MB | VIOLET 13 | &nbps; | &nbps; |

| REACTIVE MAGENTA M2R | VIOLET 14 | &nbps; | &nbps; |

| REACTIVE ORANGE M2R | ORANGE 4 | &nbps; | &nbps; |

| REACTIVE YELLOW M8G | YELLOW 86 | &nbps; | &nbps; |

| REACTIVE BLUE M2R | BLUE 81 | &nbps; | &nbps; |

- BIFUNCTIONAL DYES (‘ME’DYES)

ME dyes are low temp. high exhaust reactive dyes suitable for dyeing, padding and printing of all types of cellulosic material These dyes offer high grade of all round fastness properties. They offer excellent levelling properties and excellent alkali stability. These dyes gives exceptionally good result on various textile printing including on discharge printing except RED which gives slight yellowish stain. Fixation temp of these dyes is 60-650C.

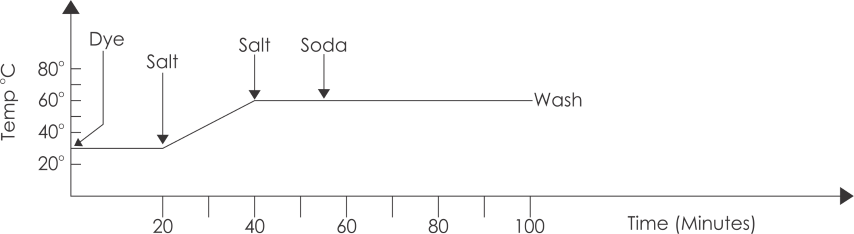

Exhust Dyeing Process:

Set dye bath at room temp. add predissolved Glauber’s salt, now enter the material and run for 20 minutes, add half amount of predissolved Glauber’s salt and continue dyeing now gradually raise temp to 60-65oc and add remaining amount of predissolved Glauber’s salt after reaching 60oC temp. Continue dyeing for 15min. further, now add soda ash solution and continue dyeing for 60min. maintain temp. 60-650C and wash the material.

Semi Continous and Continous Process: This Process for ‘ME’ dyes is same as for Reactive ‘H’ Dyes.

2. CYANURIC CHLORIDE BASED HOT DYES (‘H’ DYES)

These are named as ‘Hot Brand Dyes’. These dyes are applied under strong alkaline condition at high temp of application compared to cold brand dyes. These dyes contains very good fastness properties. These dyes are suitable particularly for printing, cotton, Viscose, Cuprammonium rayons & natural silk.

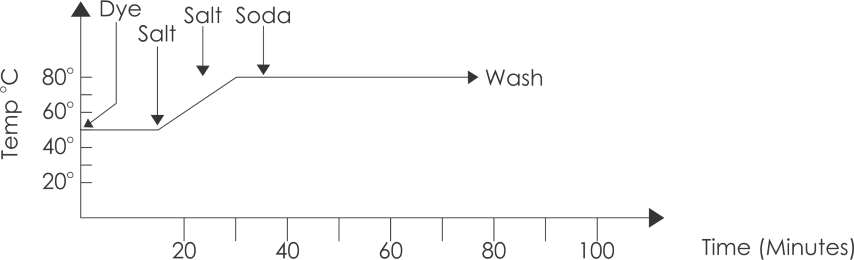

Dyeing process of these dyes is as below:

Exhaust Dyeing Process: Set dye bath at 50oC add predissolved dyestuff, enter the material and run for 15 minutes. Add half of the predissolved Glauber’s salt and continue dyeing, now gradually raise temp to 80-850C and in the mean time add remaining amount of predissolved salt and continue dyeing for 10 minutes further after attaining temp. 80-850C now add soda ash solution and continue dyeing for 30-60 minutes maintain temp. 80-850C and wash the material.

Salt and Alkali Requirements :

| Depth of Shade% | Salt (gms/lt.) | Soda Ash (gms/lt.) |

|---|---|---|

| Up to 0.5 | 30 | 10 |

| 0.5 – 1.0 | 45 | 15 |

| 1.0 – 2.0 | 60 | 15 |

| 2.0 – 4.0 | 70 | 20 |

| Above 4.0 | 90 | 20 |

Semi Continous and Continuos Process:

3. HIGH EXHAUST DYES

These dyes are suitable for deying cotton & other Cellulosic material. These dyes posses significantly higher exhaustion & fixation efficiency which results in appreciable cost reduction in comparison to other conventional reactive dyes. The high fixation and good buildup are of particular importance when dyeing polyster/cellulosic blends where liquor to material ratio is quite high. Due to higher fixation of reactive HE dyes, the drained and wash luquors after dyeing contain much less quantity of unfixed dyes in comparison to conventional reactive dyes. This facilities quicker wash off and efficient soaping. The improved stability of HE dyes gives improved batch to batch consistency.

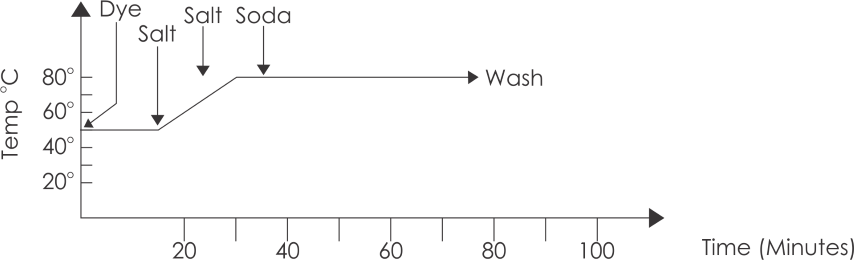

Exhaust Dyeing Process:

Set dye bath at 50oC and add predissolved dyestuff, enter the material and run for 15 minutes now add half of the predissolved glauber’s salt and continue dyeing raise the temp to 80-850C in the mean while add remaining amount of predissolved glauber’s salt and continue dyeing till temp 80-850C now add soda ash solution and, Continue dyeing for 30-60min. maintaining temp 80-85oC and wash the material.

Salt and Alkali Requirements :

| Depth of Shade% | Salt (gms/lt.) | Soda Ash (gms/lt.) |

|---|---|---|

| Up to 0.5 | 30 | 10 |

| 0.5 – 1.0 | 45 | 15 |

| 1.0 – 2.0 | 60 | 15 |

| 2.0 – 4.0 | 70 | 20 |

| Above 4.0 | 90 | 20 |

Semi Continous and Continous Process: This Process for ‘HE’ dyes is same as for Reactive ‘H’ Dyes.

Abbravations

L – Low

M – Medium

H – High

G – Good

F – Fair

P – Poor

This information is provided in good faith, to the best of our knowledge under the Laboratory working conditions & without any liabilities.